PRODUCT

PRODUCT

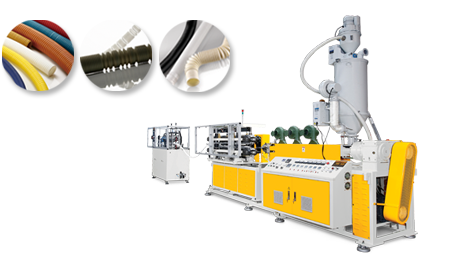

Corrugated pipe & Hose Extrusion In Line Automatic Coiler Plant Equipment

Corrugated Pipe & Hose Extrusion In Line Automatic Pipe Cutting Machine Plant

CCD Automatic Cutting Pipe Machine

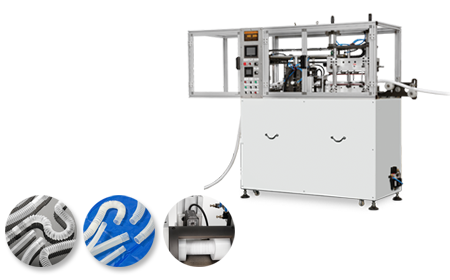

Automatic Folding & Cutting Collapsible Corrugated Pipe Machine

Semi-Auto Cutting Corruguted Pipe Machine

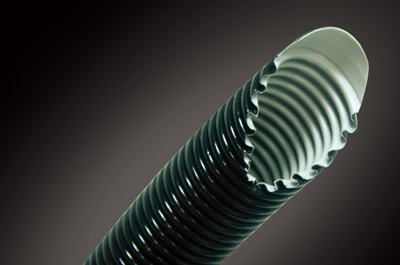

Corrugated Pipe & Hose Extrusion For The Automotive Industry

Corrugated Pipe & Hose Extrusion Line

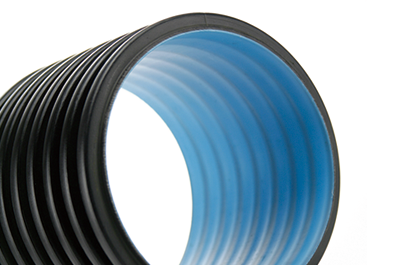

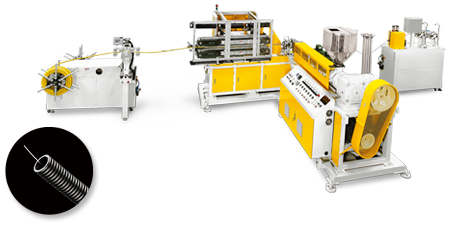

Rigid Spiral Pipe Extrusion Line

SYT-S160

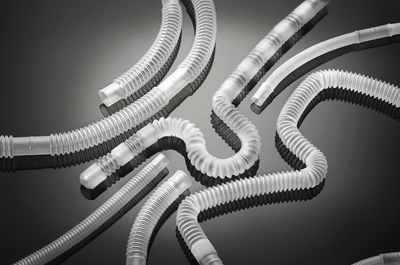

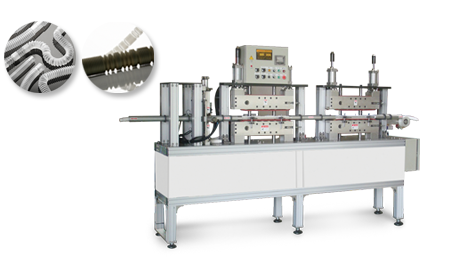

Corrugated Pipe & Hose With Metal Wire Inside Extrusion In Line Plant Equipment

Cutting Pipe Machine

Metal Wire Insert Device

SYT-CM

Pipe dividing machine

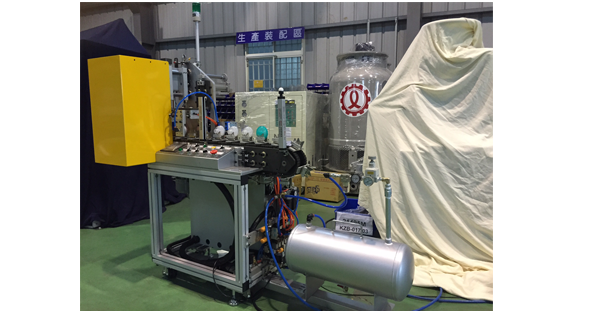

Breathing Catheter Leakage Inspecting Machine

Transducer Protector Leakage Inspecting Machine

| MODEL | SYT-CV15VA VT | SYT-C15VA | SYT-C25VA | SYT-C25BA |

|---|---|---|---|---|

| SPECIFICATIONS | ||||

| Material | PE.PP. EVA. | PE.PP. EVA. | PE.PP. EVA. | PE.PP. EVA. |

| Pipe ID. Minimum | 3 mm | 5 mm | 8 mm | 8 mm |

| Pipe OD. Maximum | 15 mm | 15 mm | 25 mm | 25 mm |

| Pipe production capacity | 4~12 M/min | 4~12 M/min | 5~15 M/min | 4~12 M/min |

| Pipe production capacity | 26~30 Kg/h | 26~30 Kg/h | 40~45 kgs/h | 40~45 kgs/h |

| Forming System | VB | VB | VB | B |

| Chain length | 1905~2032 mm | 2413~2540 mm | 2896~3048 mm | 2896~3048 mm |

| Closed chain length | 765 mm | 1015 mm | 1080mm | 1080 mm |

| Drive motor | 3/2.2 Hp/kw | 3/2.2 Hp/kw | 3/2.25 Hp/kw | 3/2.2 Hp/kw |

| Pairs of mold blocks | 60~64 Pairs | 76~80 Pairs | 76~80 Pairs | 76~80 Pairs |

| Mold cooling system | AW | AW | AW | AW |

| ENERGY REQUIRMENTS | ||||

| Hydraulic power | 2/1.5 Hp/kw | 2/1.5 Hp/kw | 2/1.5 Hp/kw | 2/1.5 Hp/kw |

| Air pressure | 6~8 Kg/cm | 6~8 Kg/cm | 6~8 Kg/cm | 6~8 Kg/cm |

| Air requirment | 161 L/min | 161 L/min | 161 L/min | 161 L/min |

| Oil tank capacity | 20 gallon | 20 gallon | 20 gallon | 20 gallon |

| Cooling water | 80 L/min | 80 L/min | 80 L/min | 80 L/min |

| Cool water lowest pressure | 1.5 | 1.5 | 1.5 | 1.5 |

| Total connected load | 40/30 Hp/kw | 40/30 Hp/kw | 36/26.5 Hp/kw | 36/26.5 Hp/kw |

| Average consumption | 30/22.5 Hp/kw | 30/22.5 Hp/kw | 27/20 Hp/kw | 27/20 Hp/kw |

| Machine dimension (LxWxH) | 1.6x1.5x2.8 m | 3.2x1.5x1.8 m | 3.8x1.6x1.7 m | 3.8x1.6x1.7 m |

| Machine weight | 3.5 Tons | 2.8 Tons | 3.2 Tons | 3.2 Tons |

| MODEL | SYT-C50BA | SYT-C50BA-L | SYT-C50BA-XL | SYT-C65BW |

|---|---|---|---|---|

| SPECIFICATIONS | ||||

| Material | PE.PP. EVA. | PE.PP. EVA. | PE.PP. EVA. | PE.PP. EVA. |

| Pipe ID. Minimum | 12 mm | 12 mm | 12 mm | 18 mm |

| Pipe OD. Maximum | 50 mm | 50 mm | 50 mm | 65 mm |

| Pipe production capacity | 3~10 M/min | 5~13 M/min | 5~25 M/min | 5~20 M/min |

| Pipe production capacity | 50~52 Kg/h | 58~60 Kg/h | 70~75 Kg/h | 70~75 Kg/h |

| Forming System | B | B | B | B |

| Chain length | 3000~3200 mm | 3800~4000 mm | 5800~6000 mm | 3800~4000 mm |

| Closed chain length | 1250 mm | 1650 mm | 2650 mm | 1650 mm |

| Drive motor | 3/2.25 Hp/kw | 3/2.25 Hp/kw | 5/3.5 Hp/kw | 5/3.5 Hp/kw |

| Pairs of mold blocks | 60~64 Pairs | 76~80 Pairs | 118~120 Pairs | 76~80 Pairs |

| Mold cooling system | AW | AW | AW | C1 |

| ENERGY REQUIRMENTS | ||||

| Hydraulic power | 3/2.25 Hp/kw | 3/2.25 Hp/kw | 3/2.25 Hp/kw | 3/2.25 Hp/kw |

| Air pressure | 6~8 Kg/cm | 6~8 Kg/cm | 6~8 Kg/cm | 6~8 Kg/cm |

| Air requirment | 240 L/min | 240 L/min | 240 L/min | 240 L/min |

| Oil tank capacity | 20 gallon | 20 gallon | 20 gallon | 20 gallon |

| Cooling water | 120 L/min | 120 L/min | 180 L/min | 200 L/min |

| Cool water lowest pressure | 1.5 | 1.5 | 1.5 | 1.5 |

| Total connected load | 47/35 Hp/kw | 55/41 Hp/kw | 64/49 Hp/kw | 65/49 Hp/kw |

| Average consumption | 36/27 Hp/kw | 41/31 Hp/kw | 45/34 Hp/kw | 45/34 Hp/kw |

| Machine dimension (LxWxH) | 4.2x1.6x1.8 m | 4.8x1.6x1.8 m | 6.2x1.8x2.2 m | 6.5x1.8x2.2 m |

| Machine weight | 3.6 Tons | 3.9 Tons | 5.2 Tons | 5.8 Tons |

| MODEL | SYT-C130BW | SYT-C200VW | SYT-C130VDW | SYT-C200VDW |

|---|---|---|---|---|

| SPECIFICATIONS | ||||

| Material | PE.PP. | PE.PP. | PE.PP. | PE.PP. |

| Pipe ID. Minimum | 50 mm | 75 mm | 50 mm | 50 mm |

| Pipe OD. Maximum | 130 mm | 200 mm | 130 mm | 200 mm |

| Pipe production capacity | 2~12 M/min | 2~12 M/min | 0~8 M/min | 0~8 M/min |

| Pipe production capacity | 190~220 Kg/h | 240~280 Kg/h | 220~240 Kg/h | 310~340 Kg/h |

| Forming System | B | VB | VB | VB |

| Chain length | 5944~6096 mm | 5893~6096 mm | 6096 mm | 6096 mm |

| Closed chain length | 2350 mm | 2150 mm | 2350 mm | 21350 mm |

| Drive motor | 7.5/5.6 Hp/kw | 7.5/5.6 Hp/kw | 7.5/5.6 Hp/kw | 7.5/5.6 Hp/kw |

| Pairs of mold blocks | 78~80 Pairs | 58~60 Pairs | 78~80 Pairs | 60 Pairs |

| Mold cooling system | C1 | C1 | C2 | C2 |

| ENERGY REQUIRMENTS | ||||

| Hydraulic power | 5/3.75 Hp/kw | 7.5/5.625 Hp/kw | 7.5/5.625 Hp/kw | 7.5/5.625 Hp/kw |

| Air pressure | 6~8 Kg/cm | 6~8 Kg/cm | 6~8 Kg/cm | 6~8 Kg/cm |

| Air requirment | 1118 L/min | 1118 L/min | 1118 L/min | 1118 L/min |

| Oil tank capacity | 50 gallon | 80 gallon | 80 gallon | 80 gallon |

| Cooling water | 470 L/min | 600 L/min | 320 L/min | 320 L/min |

| Cool water lowest pressure | 1.5 | 1.5 | 1.5 | 1.5 |

| Total connected load | 152/114 Hp/kw | 190/142 Hp/kw | 208/156 Hp/kw | 260/195 Hp/kw |

| Average consumption | 107/80 Hp/kw | 142/107 Hp/kw | 167/125 Hp/kw | 280/156 Hp/kw |

| Machine dimension (LxWxH) | 9.8x2.2x2.4 m | 11.5x2.2x2.4 m | 9.8x2.6x2.4 m | 11.5x2.6x2.4 m |

| Machine weight | 8.8 Tons | 12.8 Tons | 15.6 Tons | 18.8 Tons |

| MODEL | SYT-C500VDW | |||

|---|---|---|---|---|

| SPECIFICATIONS | ||||

| Material | PE.PP. | |||

| Pipe ID. Minimum | 200 mm | |||

| Pipe OD. Maximum | 500 mm | |||

| Pipe production capacity | 0~5 M/min | |||

| Pipe production capacity | 420~440 Kg/h | |||

| Forming System | VB | |||

| Chain length | 6096 mm | |||

| Closed chain length | 2030 mm | |||

| Drive motor | 10/7.5 Hp/kw | |||

| Pairs of mold blocks | 40 Pairs | |||

| Mold cooling system | C2 | |||

| ENERGY REQUIRMENTS | ||||

| Hydraulic power | 7.5/5.625 Hp/kw | |||

| Air pressure | 6~8 Kg/cm | |||

| Air requirment | 1538 L/min | |||

| Oil tank capacity | 80 gallon | |||

| Cooling water | 320 L/min | |||

| Cool water lowest pressure | 1.5 | |||

| Total connected load | 373/280 Hp/kw | |||

| Average consumption | 300/224 Hp/kw | |||

| Machine dimension (LxWxH) | 12.5x2.6x2.4 m | |||

| Machine weight | 26.6 Tons | |||

VT / Vertical Type

VB / Vacuum + Blow

B / Blow

AW / Air + Water separately

C1 / Chilling water directly

C2 / Chilling water directly + Air